In the world of metal processing, laser technology represents the cutting edge of innovation. This advanced system uses a high-energy density light source that is directed with extreme precision on specific areas of the material.

Thanks to this process, we can cut, weld, or engrave metals with extraordinary cleanliness and speed, guaranteeing impeccable results for every project.

Sheet metal cutting: customized processing for every need

In the industrial and metalworking sector, there are mainly two types of lasers that dominate the market. The first is the CO2 Laser, which uses a special gaseous mixture of carbon dioxide activated through electrical discharges. This pioneering technology in the production field stands out for its remarkable operating speed, constant reliability, and contained system costs. It is particularly suitable when high-quality sheet metal cutting is required.

The second type is the Fiber Laser, where the light beam works in synergy with low-power diodes that allow current to flow unidirectionally. Compared to the CO2 Laser, this technology operates with a lower wavelength, making it ideal for cutting more complex metal sheets.

Fiber systems excel for their exceptional reliability, operational longevity, low energy consumption, and reduced maintenance requirements. For these reasons, they are the preferred choice for both welding operations and custom sheet metal cutting, as well as for micro-processing interventions.

Steel cutting and stainless steel cutting: versatility for modern industry

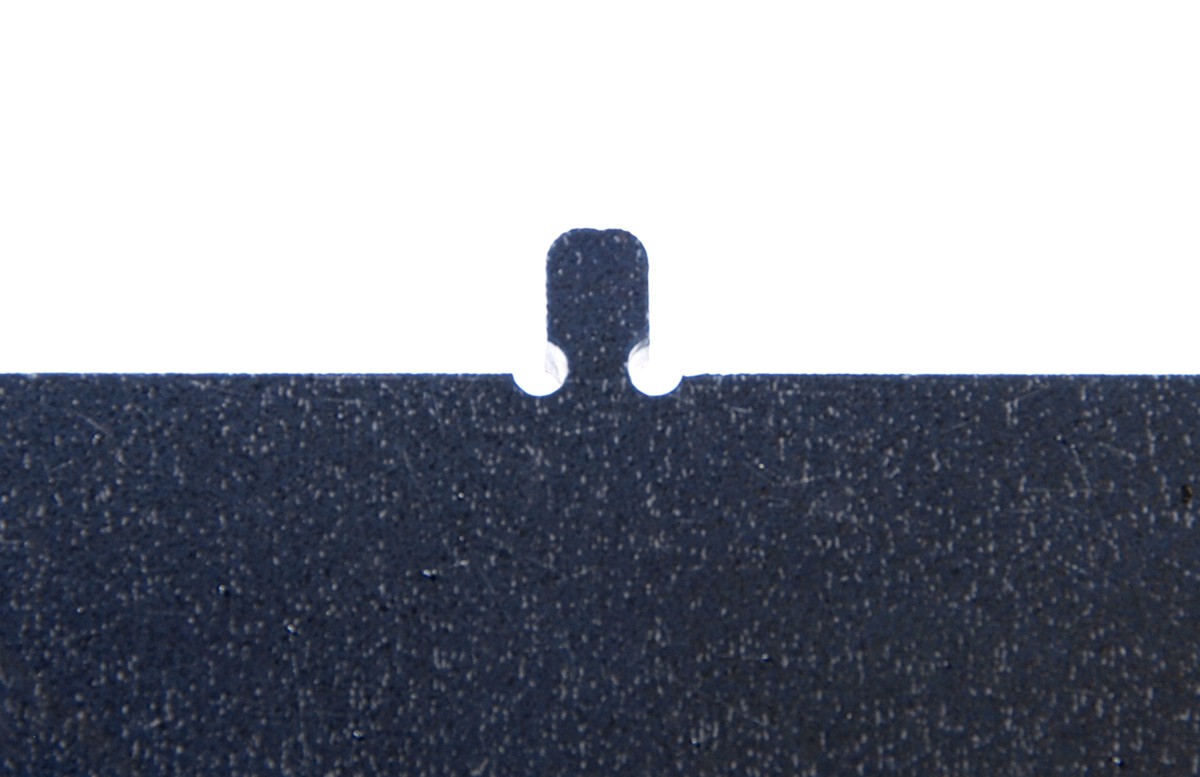

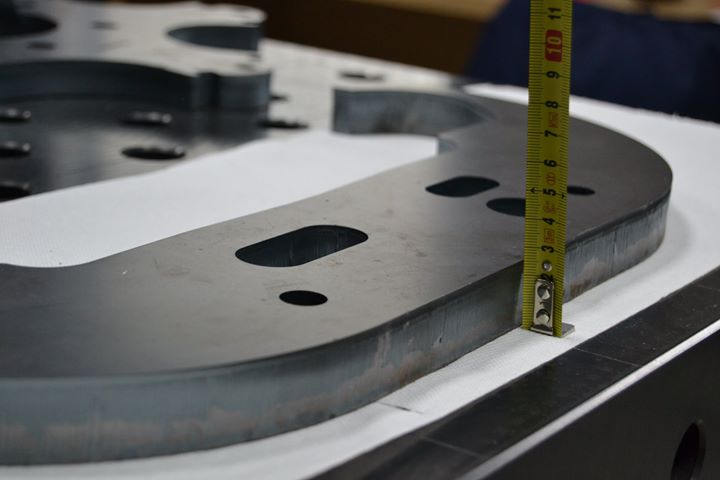

Laser steel cutting technology employs a concentrated light beam that, generating extremely high temperatures, melts and vaporizes the material along the programmed path. This innovative method allows for defined and meticulous cuts on stainless steel, minimizing any risk of thermal deformation or edge imperfections.

The benefits of stainless steel cutting are numerous and significant. The extraordinary accuracy allows for the creation of elaborate geometric shapes while respecting minimal tolerances. The versatility of the technology makes it applicable to multiple thicknesses and types of metals. In terms of efficiency, we find considerably reduced processing cycles and better material utilization with less waste. The resulting edges are so smooth and defined that they often require no additional finishing, greatly facilitating subsequent production processes and reducing the overall costs of laser steel cutting.

Aluminum laser cutting: efficiency and clean results

Laser engraving offers considerable advantages over other traditional techniques, making it the optimal solution for aluminum processing. Among the main strengths, we find the exceptional precision with which the material can be engraved.

Thanks to laser technology, even the most minute and complex details can be transferred onto aluminum with surprising definition.

The process also stands out for its remarkable speed and efficiency, maintaining high performance even with significant production volumes. Unlike conventional techniques such as milling or punching, laser cutting of aluminum does not produce unwanted residues, guaranteeing impeccable and well-defined surfaces.

Flexibility represents another decisive advantage: thanks to the latest generation software, it is possible to create practically any design, from simple writings and logos to elaborate graphics and complex textures. In summary, when looking for a method to work with aluminum, laser engraving is undoubtedly the ideal answer.

Aluminum laser processing presents some technical challenges to consider: the highly reflective nature of the material can interfere with the laser beam, making careful calibration of operating parameters crucial. The excellent thermal conductivity of aluminum involves rapid heat distribution, a factor that can affect the effectiveness of laser cutting on aluminum. To prevent oxidation of cutting edges, the use of special gases such as nitrogen or oxygen during the cutting process is often necessary.

Laser engraving on metal: clear and lasting details

Laser technology allows for marking on metal through various methodologies. With annealing marking, the generated heat locally modifies the metallic structure, creating a chromatic change without altering the surface, which remains perfectly intact.

Laser engraving on metal instead involves the controlled vaporization of the material, producing marks that are extremely resistant to wear and long-lasting. The removal of the surface layer by laser occurs quickly, creating laser engravings on metals with marked contrast and optimal readability.

Engraving on steel and stainless steel: the power of precision

Steel engraving undoubtedly represents the most effective method for marking metals, including stainless steel.

The advantages offered by laser technology are multiple: it guarantees precise, clear, easily readable, and quickly executed laser engraving on steel. Versatility is another considerable strength, as this technique adapts perfectly to both malleable metals like aluminum and more resistant materials, allowing professional quality stainless steel engravings in any production context.

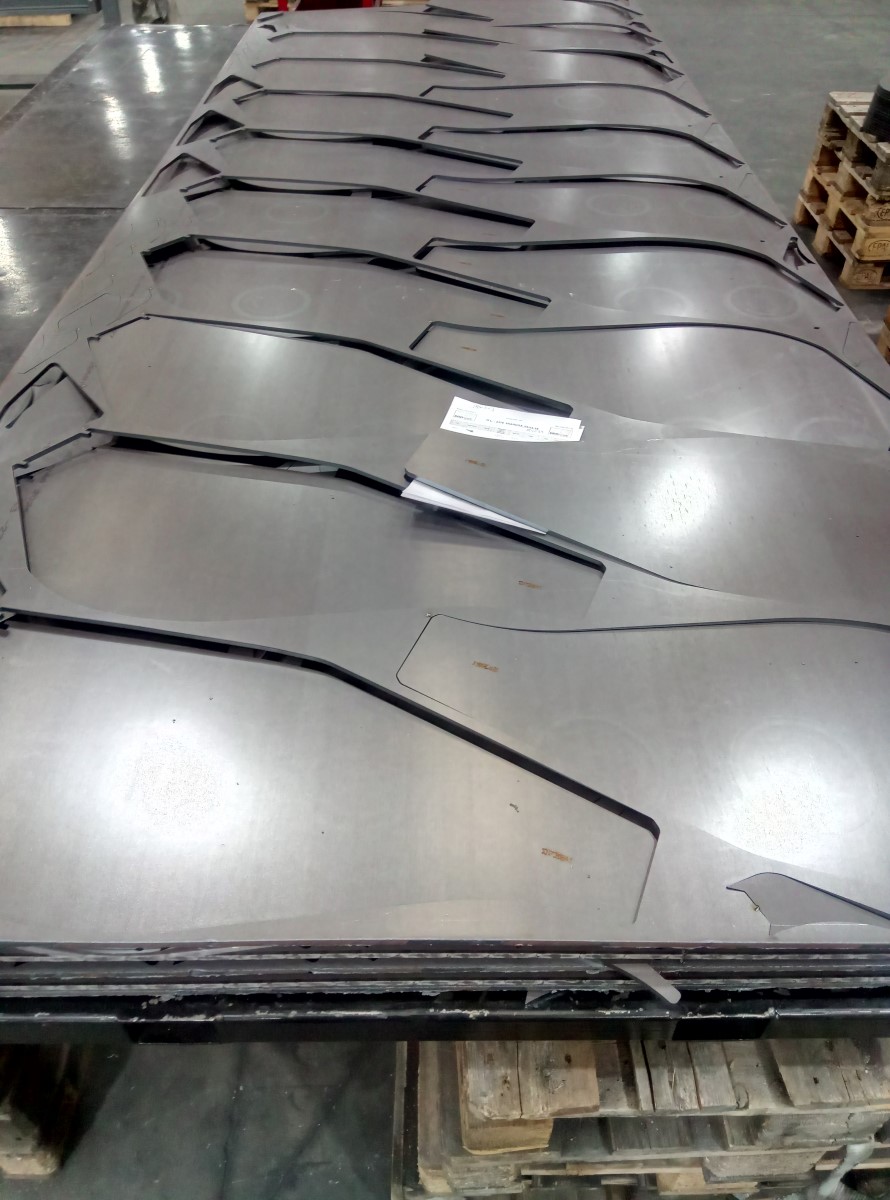

Processing Sheet metal Laser Cutting

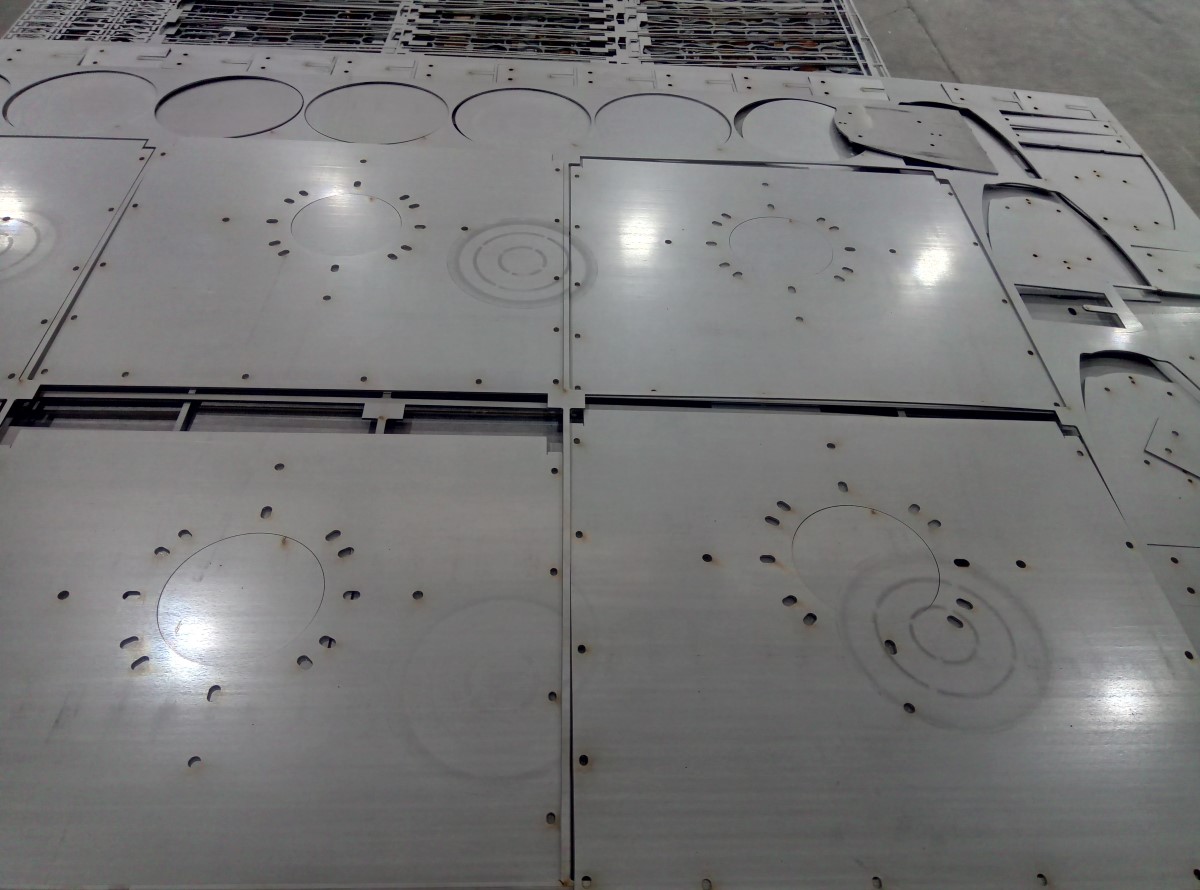

Perforated, Punctured, Micro-perforated, and Decorative Sheets: functionality and aesthetics

Perforated sheets can be produced in different configurations to adapt to multiple applications.

Square mesh perforated sheet offers a larger open area and improves visibility through the material. Round perforated sheet represents the most widespread and versatile solution among all available punctured sheets.

To respond to specific needs, we also create custom micro-perforated sheets, creating a final product that satisfies any requirement, both functional and aesthetic. Perforated and decorative sheets add a design element to projects that require not only functionality but also a distinctive visual impact.

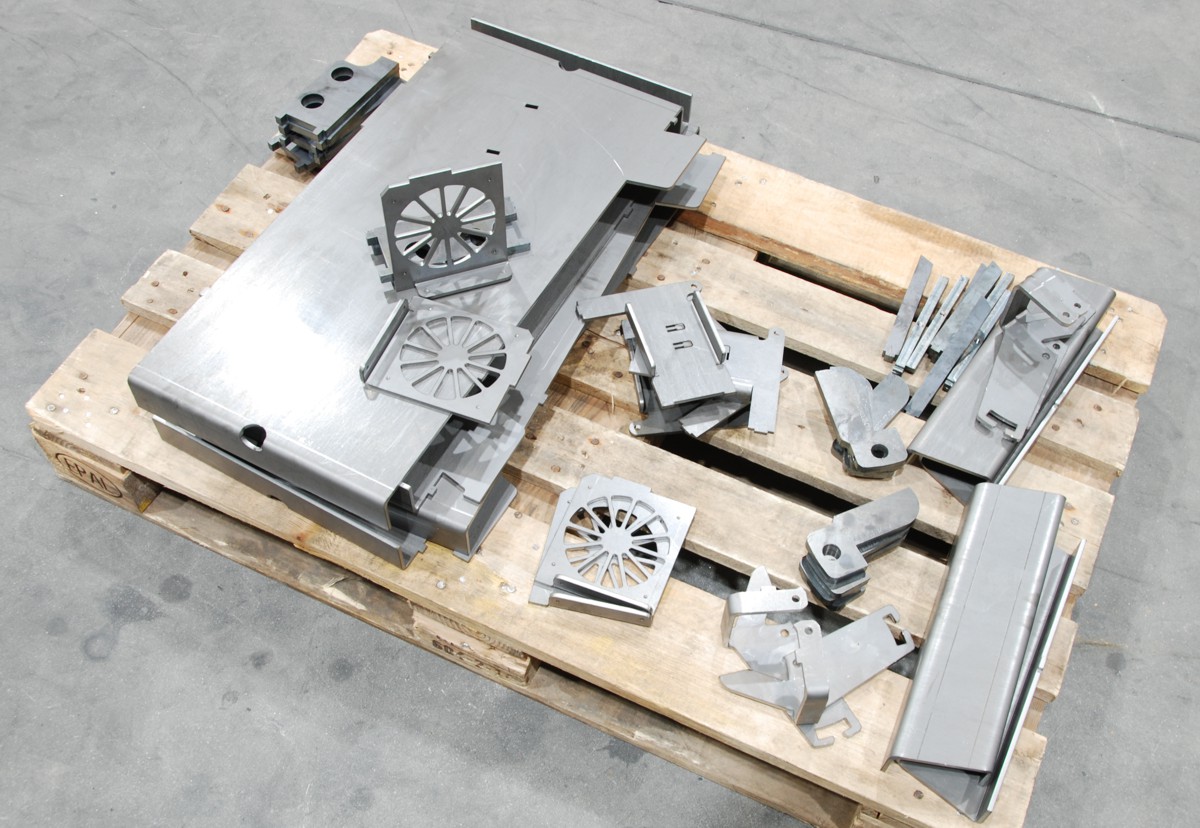

Shaping, Bending, and Complex Sheet Metal Processing

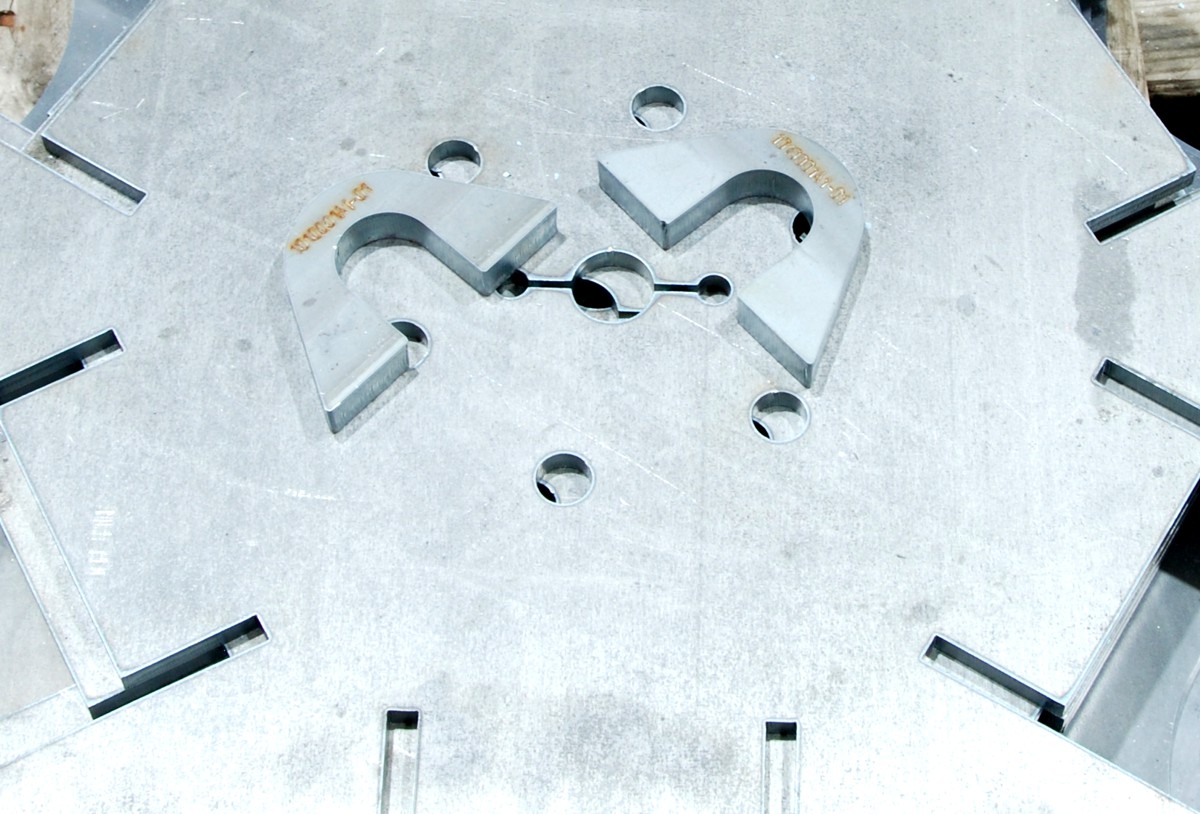

After laser cutting, we dedicate ourselves to transforming the base sheet metal into a finished product perfect in dimensions, finishes, shape, and thickness. The shaping of steel sheets consists of processes that follow laser cutting and are aimed at defining a precise profile to the metal sheet, mainly through the creation of strategically positioned holes and slots.

The shaped sheet metal is then subjected to the bending process, a cold mechanical processing that permanently deforms the metal through the controlled application of bending forces. This technique, combined with cutting and bending sheet metal, is fundamental in the metallurgical industry to create a wide range of components and semi-finished products used in numerous sectors, from carpentry to construction, from transport to automotive.

Our experience in sheet metal cutting processing allows us to offer complete solutions that respond to the most specific needs of our customers.

Fiber Laser and Advanced Technologies for metal cutting

The fiber laser uses a special optical fiber to transmit the light beam, guaranteeing extraordinarily high cutting precision.

Fiber laser systems represent the ideal solution for sheet metal cutting, thanks to their ability to generate an extremely concentrated and stable beam, capable of easily passing through metallic materials of various thicknesses.

The use of this advanced technology allows for superior quality results, with perfectly defined edges free of imperfections, significantly reducing the need for subsequent processing.

Our cutting-edge laser allows cutting with millimetric precision, offering results impossible to obtain with traditional methods.

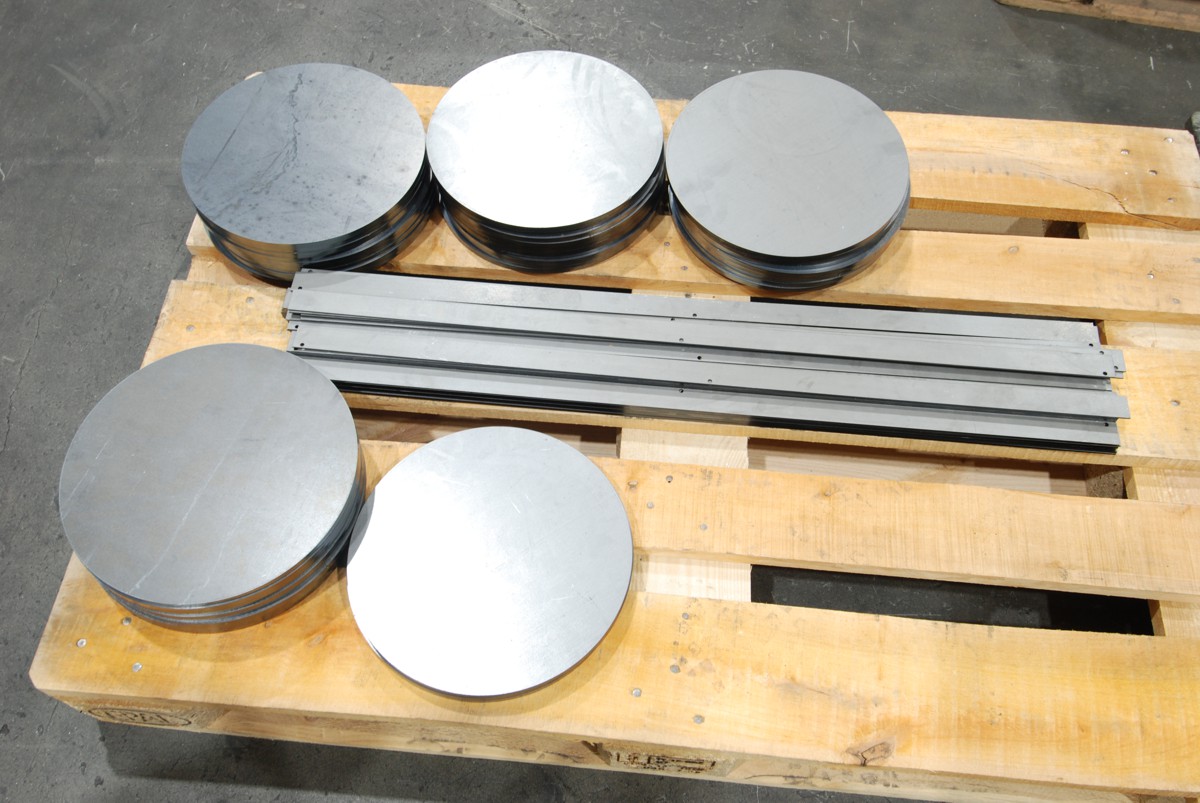

The metals we work with

Proven experience

Our consolidated expertise guarantees excellent results in every type and complexity of industrial processing.

Cutting-Edge Technology

Our comprehensive and innovative machinery allows us to carry out every processing step in-house, without the need for external intervention.

High-Volume Management

Thanks to a qualified team, advanced equipment, and know-how, we efficiently handle large-scale productions, whether individual or in kits.

Punctuality and reliable lead times

Established processes and parallel production lines enable us to consistently meet agreed deadlines.

Traceability

Computerized monitoring systems make it possible to track every component throughout the entire production cycle.

High Customer Loyalty

The combination of our professional and technical qualities translates into lasting and stable relationships with all our partner clients.

Excellent precision

We immediately identify the ideal process for each production task, minimizing time and costs.

Integrated logistics

We manage the entire distribution chain by collaborating with a network of selected couriers for maximum reliability and punctuality.