The laser tube cutting process represents an extraordinary technological innovation that uses a concentrated laser beam to section metal tubes and profiles with extreme precision.

This cutting-edge methodology employs fiber laser technology, universally recognized for its reduced energy consumption and extraordinary ability to achieve impeccable cuts on materials such as stainless steel and aluminum.

Laser cutting of tubes and tubular profiles: versatility for every section and material

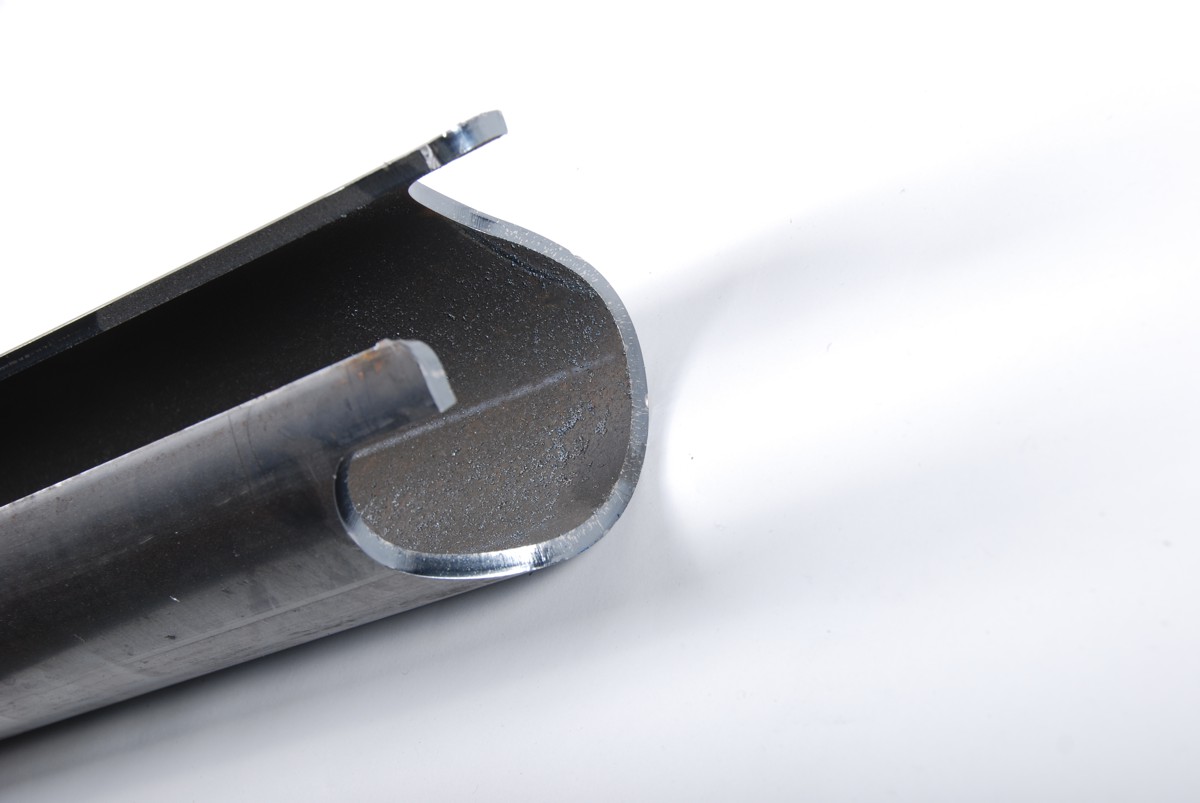

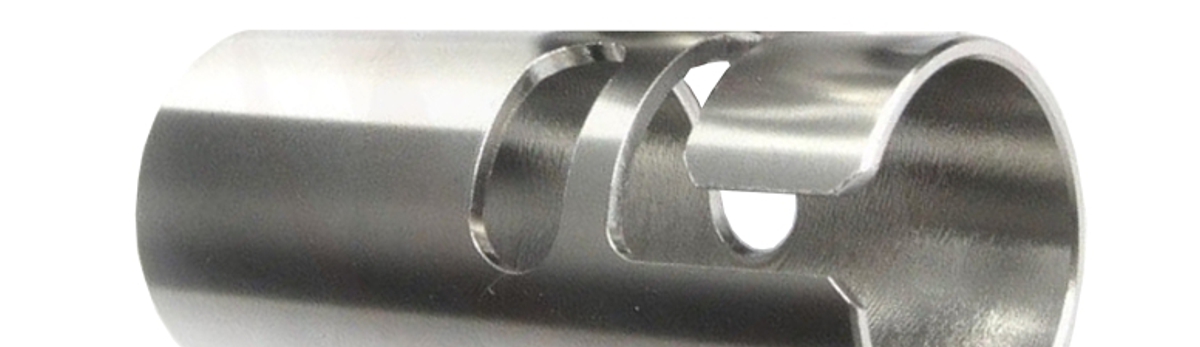

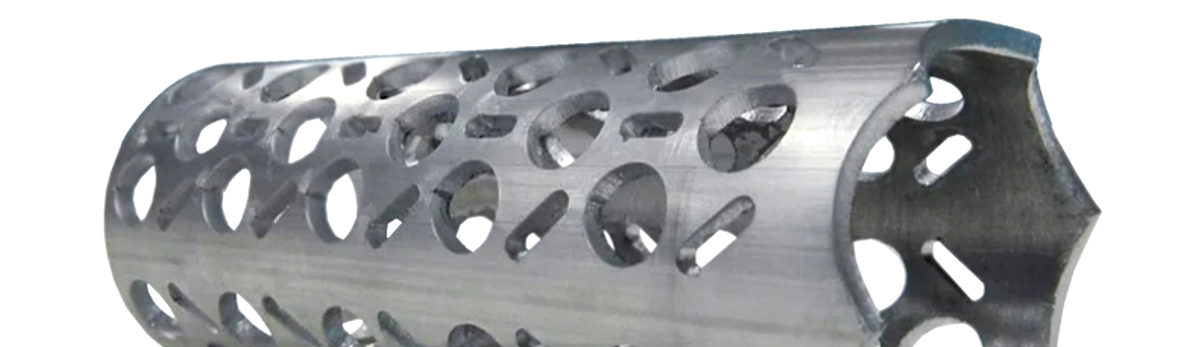

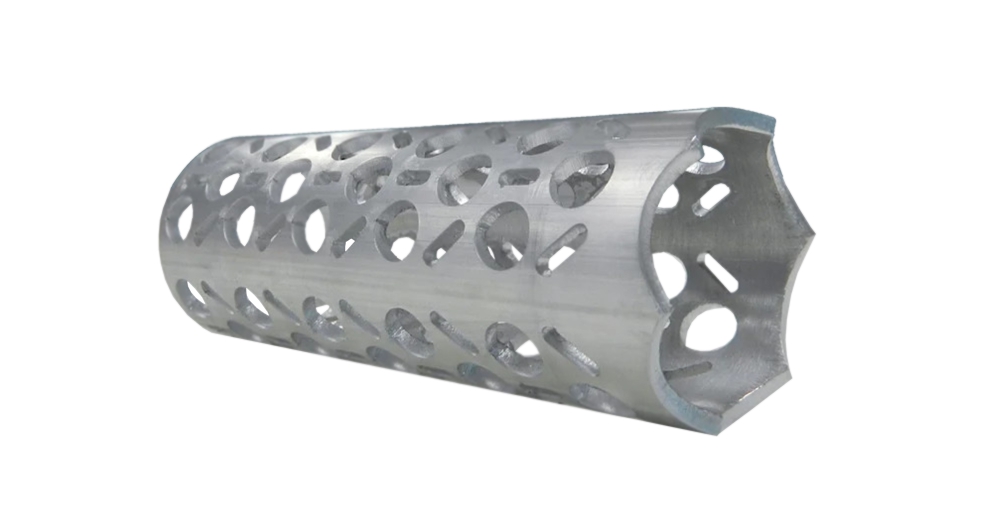

Our company specializes in tube cutting for round, rectangular, and oval shapes, adapting perfectly to any design requirement. Precision is the fundamental element in our laser tube cutting methods, ensuring burr-free processing with minimal tolerances. Thanks to the technology employed, we are able to make complex cuts while maintaining superior quality compared to traditional methods.

Tubular cutting with laser technology also offers significantly higher processing speed than conventional systems, allowing finished components to be obtained in significantly reduced times, thus increasing company productivity. This translates into faster deliveries and greater market competitiveness.

An additional advantage of laser tube cutting is the extraordinary design flexibility it provides. Thanks to the ability to make cuts of complex geometries and variable dimensions, this technique allows the development of customized components that perfectly meet our customers’ specific requirements.

Laser cutting on steel and stainless steel: precision without compromise

The process of cutting steel through laser technology represents a sophisticated but extremely efficient procedure. It all begins with the correct positioning of the tube inside the machine, preparing it to allow the laser beam to move with absolute precision along the programmed cutting path.

Once properly positioned, the laser beam is focused on the tube surface to make the desired cut. The accuracy of the operation is guaranteed by the calibrated power of the laser and the advanced control system that guides the machine with millimeter precision during all processing phases.

During the stainless steel cutting process, the material is exposed to the intense heat generated by the laser beam, which causes the fusion and subsequent vaporization of the metal, thus creating a clean and precise cut without any deformation. This is particularly important when cutting stainless steel, a material that requires particularly accurate processing.

At the end of the iron cutting process, the piece is cooled and removed from the machine. The component thus obtained can be immediately used or, if necessary, subjected to further finishing processes. Laser technology cuts with such precision that it significantly reduces the need for subsequent processing, optimizing production times and reducing overall costs.

Aluminum laser cutting: quick and clean solutions for every tube

Our experience in aluminum cutting allows us to work with tubular profiles of any section, offering our customers maximum freedom in designing their products. Laser-cut aluminum represents an ideal solution for numerous industrial applications thanks to the lightness and strength of this material.

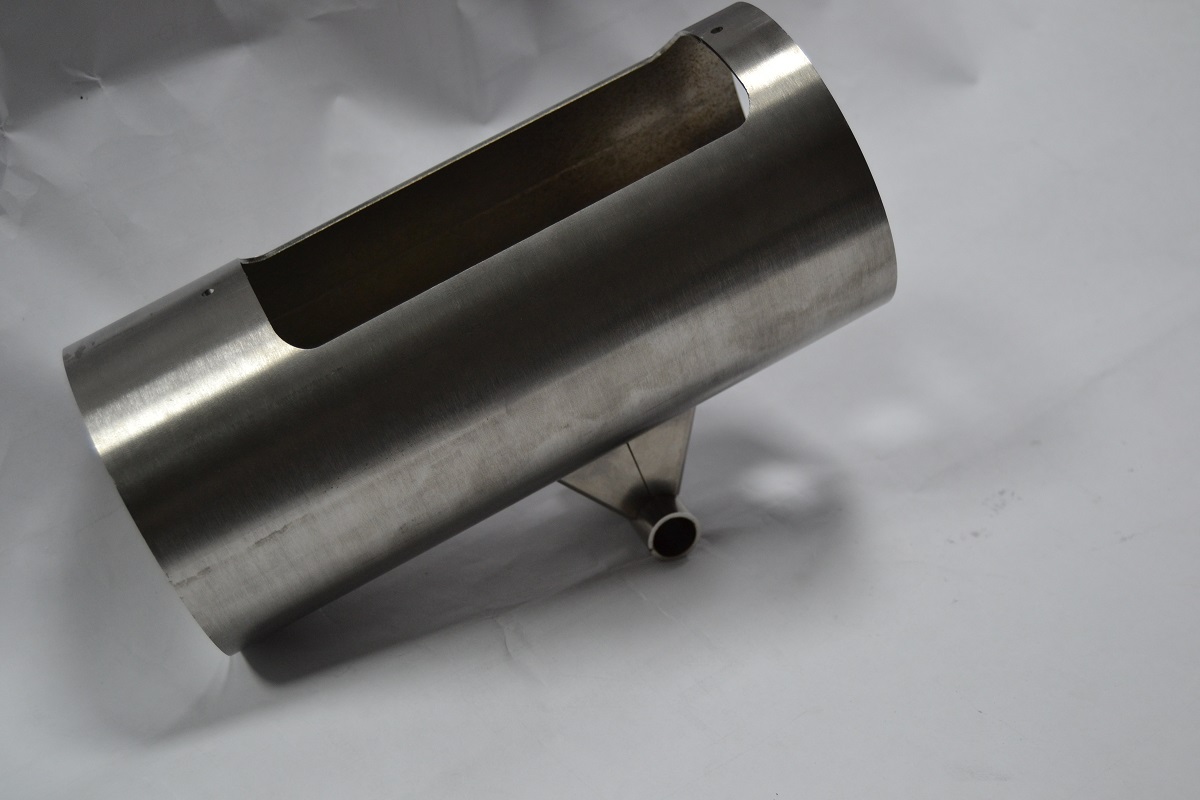

We are equipped to handle loading and unloading of tubes up to 15 meters in length as a single piece, ensuring laser cutting of aluminum tubes using optical fiber for tubes and profiles with diameters up to 355 mm. Laser cutting of aluminum ensures clean edges without imperfections, an essential characteristic for components that require high quality standards.

The aluminum laser cutting service we offer allows customers to send their projects and quickly receive a personalized quote, while our experience in aluminum sheet cutting allows us to satisfy even the most complex requests.

Processing Laser tube cutting

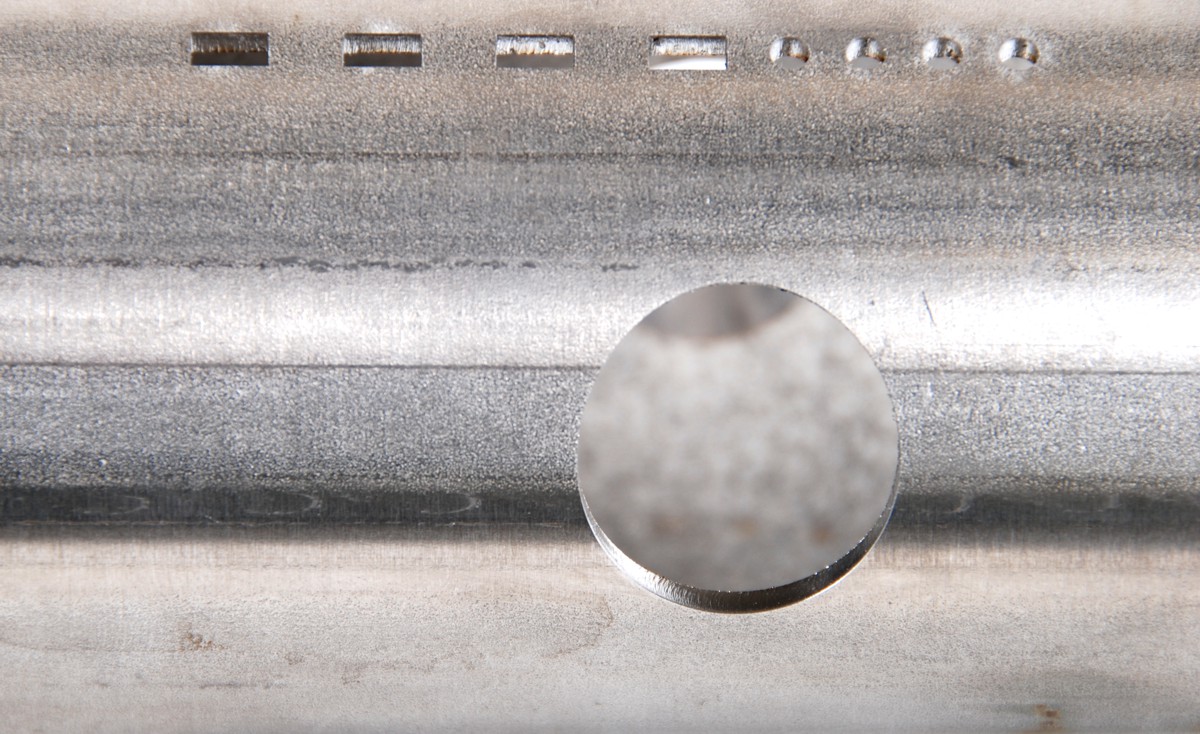

Laser engraving and cutting on metal tubes

At Lasercutting, we can perform various processes on metal tubes that go beyond simple cutting.

Our technology allows us to perform operations with extreme precision such as drilling, chamfering, metal laser engraving, grooving, vertical cutting, and various types of notches. Metal engraving represents an ideal solution for component customization and for the application of permanent identification codes.

Thanks to laser engraving, it is possible to create high-quality markings that resist over time and do not alter the structural characteristics of the material. Our laser cutting technology guarantees impeccable results even in the most complex processes, while the experience of our technicians ensures that each project is carried out according to the customer’s specific requirements. The laser cutting system we use is among the most advanced available on the market.

Fiber laser and advanced technologies for tube cutting

Fiber laser represents the most advanced technological evolution in the metal tube cutting sector. The fiber laser systems we use offer numerous advantages over traditional methodologies, from the extraordinary precision of the cut to the significant reduction in operating costs.

The versatility of this technology allows us to tackle complex processes that would be impossible with other methodologies.

Our tube cutting laser service stands out for its high execution speed and energy efficiency, characteristics that translate into lower environmental impact and reduced delivery times. Operational safety is another fundamental aspect: Lasercutting online procedures are designed to minimize risks during all phases of processing.

We also offer an online metal laser cutting service with personalized quotes, allowing customers to quickly obtain an online metal laser cutting offer suited to their needs.

Laser cutting of aluminum profiles and tubes

Aluminum laser cutting is used in the processing of tubes and profiles of various dimensions and sections, intended for the creation of components used in numerous industrial sectors such as furniture, lighting, components, light carpentry, and aeronautics. Aluminum is used not only in traditional commercial sections such as square, round, and rectangular tubes, but also in special profiles, open, angular, flat, and U or L-shaped.

The reflective nature of aluminum requires the exclusive use of machinery equipped with fiber optic lasers, as the use of CO2 sources could cause serious damage to the equipment. Our aluminum profile cutting service guarantees excellent results even on complex geometries, while the profile laser cutting technology we use ensures precise and clean cuts on any type of section.

Laser cutting for automotive: tailored solutions for frames and tubular structures

In the automotive sector, laser cutting represents an essential solution for the production of frame components, exhaust system piping, and metal support structures. Our experience in laser cutting for the automotive sector allows us to offer customized solutions that guarantee maximum precision and safety, fundamental requirements in a sector where tolerances are minimized.

The metals we work with

Proven experience

Our consolidated expertise guarantees excellent results in every type and complexity of industrial processing.

Cutting-Edge Technology

Our comprehensive and innovative machinery allows us to carry out every processing step in-house, without the need for external intervention.

High-Volume Management

Thanks to a qualified team, advanced equipment, and know-how, we efficiently handle large-scale productions, whether individual or in kits.

Punctuality and reliable lead times

Established processes and parallel production lines enable us to consistently meet agreed deadlines.

Traceability

Computerized monitoring systems make it possible to track every component throughout the entire production cycle.

High Customer Loyalty

The combination of our professional and technical qualities translates into lasting and stable relationships with all our partner clients.

Excellent precision

We immediately identify the ideal process for each production task, minimizing time and costs.

Integrated logistics

We manage the entire distribution chain by collaborating with a network of selected couriers for maximum reliability and punctuality.