Lasercutting, specialized division of Carpenteria Canfora, supports metal workshops in the preliminary and preparatory phase of manufacturing their products.

Based in Lombardore (TO), we are the technical-industrial partner for precision machining, designed to integrate perfectly into the production processes of metal workshops.

Laser Cutting and Metal Workshop

We provide metal workshops with an advanced production line for laser cutting of metal profiles, optimized to ensure maximum precision, efficiency, and repeatability.

Our processes are designed to adapt to the needs of those operating in the medium-heavy metal fabrication sector, with specific services including:

- Cut-bend: We create complex geometries that facilitate subsequent manual bending, reducing the need for additional tooling.

- Drilling: We create precise openings for subsequent mechanical operations, optimizing timing and alignments.

- Marking: We provide permanent identification of components (logos, codes, assembly references) through non-invasive laser engraving.

- Interlocking: We design functional cuts for immediate assembly, eliminating the use of templates or additional accessories.

Cut and Bend

For metal workshops that require pre-bent components, we offer an integrated cutting + bending process based on direct communication between the software of the two systems. The system automatically calculates material deformation and adapts the processes to ensure millimeter precision from the first cycle.

The advantages for metal workshops

- High precision in the preparation of components to be assembled.

- Reduction of material waste.

- Certain timeframes and quick deliveries, thanks to a warehouse that is always stocked with raw materials.

- Repeatability for series production.

Additional services to complete the metal workshop process

We also offer partner metal workshops additional custom machining to support subsequent production phases:

- Press Bending: Ideal for creating prototypes or small series without the need for expensive molds. Possibility of obtaining multiple bends and different angles with the same equipment.

- Robotic Welding: We have robotic systems to provide pre-welded components, ready for integration into more complex structures.

Collaborating with Metal Workshops: our core business

Our goal is to simplify and accelerate the work of metal workshops, offering technical machining performed with expertise and cutting-edge technology.

Although we can produce finished products, we can also put our production capacity at the service of those who build, assemble, and install.

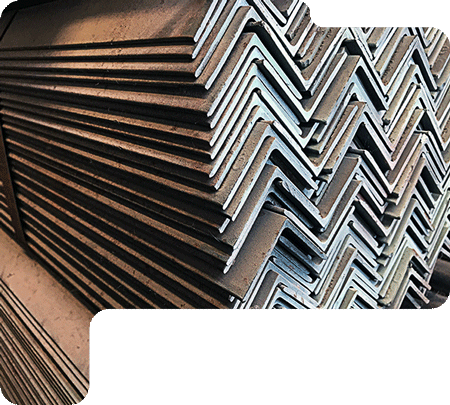

The metals we work with

Proven experience

Our consolidated expertise guarantees excellent results in every type and complexity of industrial processing.

Cutting-Edge Technology

Our comprehensive and innovative machinery allows us to carry out every processing step in-house, without the need for external intervention.

High-Volume Management

Thanks to a qualified team, advanced equipment, and know-how, we efficiently handle large-scale productions, whether individual or in kits.

Punctuality and reliable lead times

Established processes and parallel production lines enable us to consistently meet agreed deadlines.

Traceability

Computerized monitoring systems make it possible to track every component throughout the entire production cycle.

High Customer Loyalty

The combination of our professional and technical qualities translates into lasting and stable relationships with all our partner clients.

Excellent precision

We immediately identify the ideal process for each production task, minimizing time and costs.

Integrated logistics

We manage the entire distribution chain by collaborating with a network of selected couriers for maximum reliability and punctuality.