LaserCutting: Laser Cutting Company

LaserCutting is a production line of Carpenteria Canfora, specialized in laser cutting of tubes and sheets (CO2 and Fiber). It is based in Lombardore, in the province of Turin, just a few kilometers from Caselle Torinese Airport and the A4 Turin/Milan highway exit.

Today, our production ranges from small-scale jobs to large industrial orders, with a flexible structure that can adapt to the specific needs of our clients.

LaserCutting: Laser Cutting Company

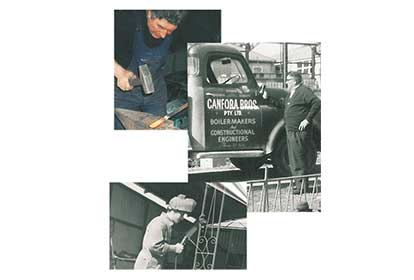

In 1970, the company moved from Puglia to Piedmont, opening its first location in Turin under the name Carpenteria Canfora.

In 1995, the metal workshop moved to Leinì to expand production to 600 m².

In 2000, the first Laser Cutting machines were purchased, and a dedicated production line was created under the name LaserCutting.

In 2009, it became necessary to double the space, reaching 1,300 m².

In 2012, it moved to Lombardore, its current location with 5,000 m² of covered space and 6,000 m² of uncovered area.

Today, the company is continuously expanding and has diversified its production with a highly specialized Laser cutting center.

Proven experience

Our consolidated expertise guarantees excellent results in every type and complexity of industrial processing.

Cutting-Edge Technology

Our comprehensive and innovative machinery allows us to carry out every processing step in-house, without the need for external intervention.

High-Volume Management

Thanks to a qualified team, advanced equipment, and know-how, we efficiently handle large-scale productions, whether individual or in kits.

Punctuality and reliable lead times

Established processes and parallel production lines enable us to consistently meet agreed deadlines.

Traceability

Computerized monitoring systems make it possible to track every component throughout the entire production cycle.

High Customer Loyalty

The combination of our professional and technical qualities translates into lasting and stable relationships with all our partner clients.

Excellent precision

We immediately identify the ideal process for each production task, minimizing time and costs.

Integrated logistics

We manage the entire distribution chain by collaborating with a network of selected couriers for maximum reliability and punctuality.